Imaging and Machine Vision Europe talks to Paul Wilson, Managing Director of Scorpion Vision, about the landscape of AI adoption in vision-guided robotics.

Imaging and Machine Vision Europe: What are the benefits of AI in vision-guided robotics (VGR)?

Paul Wilson: The advent of AI presents an exciting opportunity to enhance the capabilities and performance of vision-guided robotic systems. Repeatability as a result of enhanced feature extraction is the number one benefit of applying AI to machine vision.

The camera builds up a profile of a foodstuff or item in 3D and analyses it for reference features to create an approximation of what the vision system is looking for. AI is then applied to enhance feature extraction through ‘deep learning’.

With 3D machine vision alone, up to around 80% reliability is achievable; when you overlay that with AI, you can achieve close to 100%.

IMVE: Is AI seeing widespread adoption in VGR?

PW: The pace of adoption is undoubtedly accelerating. We have observed that attitudes towards AI have shifted considerably in the last two to three years. Businesses have gone from talking about AI in a futuristic and abstract sense to thinking in practical terms about how AI can enhance their vision-guided robotic applications. They have a much better understanding of what AI can do for them.

However, there are some barriers to the wider adoption of AI. The biggest of these is the knowledge gap that currently exists in the integration of AI with VGR systems. Integrating AI into an automation system that works 100% of the time requires a deep understanding of camera hardware and software, robotics and AI. Few systems integrators have the skillset to be able to build and program AI-powered vision-guided robotic systems.

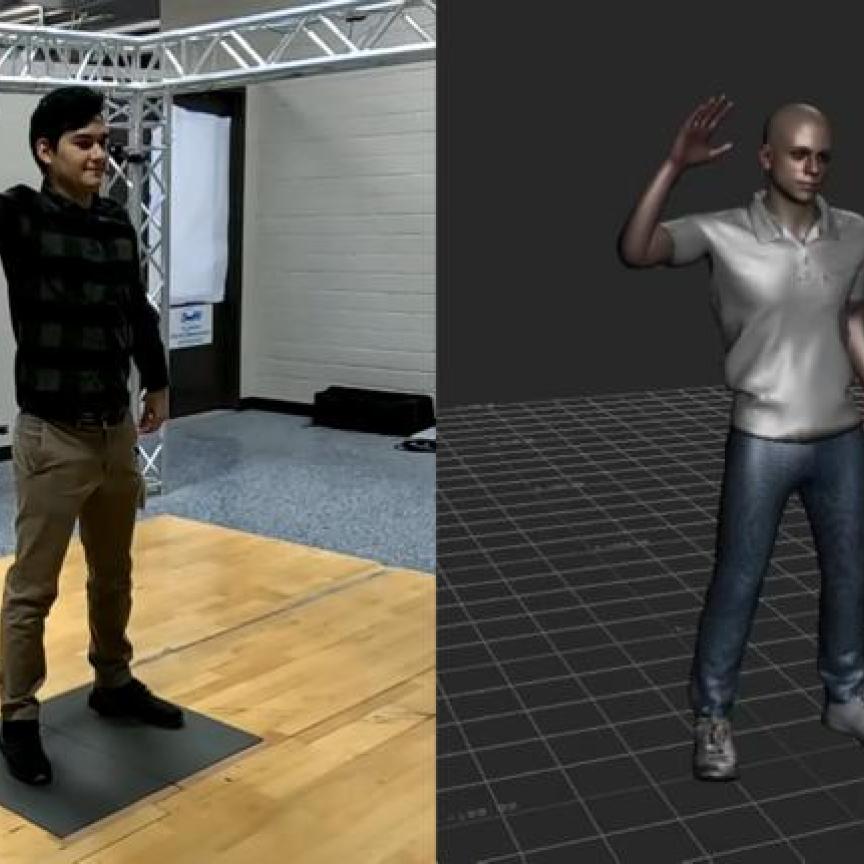

Scorpion Vision has recently started working with a company called Mech Mind, whose suite of AI + 3D vision solutions for robots combines high-performance industrial cameras with intelligent platform software (Image: Scorpion Vision)

IMVE: Which applications will see the most benefit from this?

PW: The applications that stand to benefit most from AI are those operations that are still being performed by humans because the products are inherently variable. The inspection and trimming of fresh produce, including fruit, vegetables, meat and seafood, are all applications where AI has the potential to make huge performance improvements.

Employing AI in food processing has provided the missing link that is needed to provide a high level of repeatability with subject matter that does not conform. With AI, vision systems can be taught to work with variability without it impacting on inspection performance or accuracy. By applying AI to 3D machine vision, we have succeeded in achieving a very high level of repeatability, which is the key to high yield and minimal wastage. This solution has been tried and tested in a range of applications, from topping and tailing corn on the cobs, swedes and leeks, to de-coring lettuce, removing the outer leaves from sprouts and de-shelling seafood.

For straightforward applications, such as random bin picking or palletising, it is possible to incorporate ‘off the shelf’ AI+3D robot vision products into robot vision installations (Image: Scorpion Vision)

IMVE: How are factory customers responding? Are they showing enthusiasm towards the technology?

PW: Because there has been so much hype around AI, there is a lot of curiosity and interest. Not all of this translates into serious intent to invest in AI-driven automation, but uptake is growing.

We have supplied a number of systems to the fresh produce industry, where there is quite a compelling case for adopting AI as the yield and quality improvements are considerable and quantifiable. As well as the tangible benefits, what companies really seem to like about our solutions is that we take responsibility for the entire project – we have the software, hardware and engineering expertise to design complete line-ready systems in-house.

IMVE: How are robotics firms working with imaging & machine vision firms to realise these solutions?

PW: The diverse skill sets that these projects demand are one of the biggest challenges when it comes to adopting AI.

For complex and precision applications, the only approach that produces robust and reliable results is to build AI vision systems from scratch. We already have our proven automation platform, so have been able to build AI into that with great success. Our AI cameras are designed from the ground up to suit the application. That means we can optimise the design and the parameters to enhance the performance of that product. If we want to use more powerful lighting or move the lighting outside the camera, for example, we can, because we have complete control over the build.

The inspection and trimming of fresh produce, including fruit, vegetables, meat and seafood, are all applications where AI has the potential to make huge performance improvements(Image: Scorpion Vision)

For straightforward applications, such as random bin picking or palletising, it is possible to incorporate ‘off the shelf’ AI plus 3D robot vision products into robot vision installations. This automates much of the build process, dramatically reducing integration, development and programming time (and cost). Scorpion Vision has recently started working with a company called Mech Mind, whose suite of AI + 3D vision solutions for robots combines high-performance industrial cameras with intelligent platform software.

The core hardware module is the Mech-Eye industrial camera, and three complementary software applications complete the package: Mech-Vision is the machine vision software element; Mech-Viz is the bundled robot programming software and Mech-DLK enables the creation of deep learning applications. When these building blocks are used in combination, users can quickly design automation applications. This is something we expect to see more of in the future.