Romanian robotics and automation hardware developer ADAPTA Robotics has received €2 million investment from the Catalyst Romania fund, to enhance distribution partnerships for its products, including retail scanner ERIS.

With clients including Zebra Technologies, Ypsomed and Nissan, ADAPTA Robotics developers, sells and licences flexible products like the MATT Robot, used mainly for product testing in the automotive, electronics and medical sectors, and ERIS scanner, a push-bot retail scanner designed to quickly and effortlessly address on-shelf availability and pricing issues.

With a €2 million investment from the Catalyst Romania fund, alongside other investors such as the business angel community Women Invest in Tech (WIT), ADAPTA Robotics now aims to enhance its offerings and strengthen its partnerships.

From the moment we met the founding team of ADAPTA Robotics, we were impressed by their deep knowledge and passion for the robotics field,” said Alin Stanciu, Partner at Catalyst Romania. “Even more notable was how they transformed that passion into a thriving business with real-world impact.”

On the other side of the deal, meanwhile, speaking on Catalyst Romania’s suitability as an investment partner, ADAPTA Robotics CEO Mihai Crăciunescu said: “With Catalyst’s excellent track record and extensive experience, we look forward to building on this momentum and scale our operations, while continuing to improve our globally sold products.”

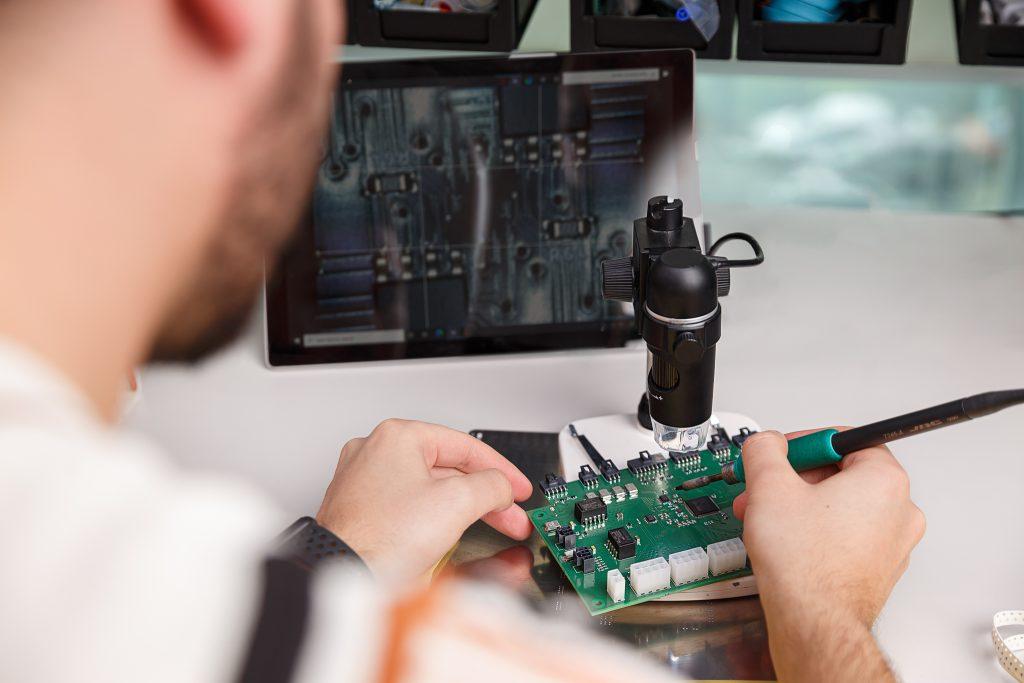

Image: Andrei Cojan/Adapta Robotics

ERIS, the human-controlled push scanner for retail

One of those key products developed, manufactured and licenced by ADAPTA, is ERIS (or Effective Retail Intelligent Scanner). Designed for adaptability, ERIS integrates with a retail space in real-time, collecting and processing data like the live status of a store’s database with the live status of the barcodes actually out on the shelves.

With each scanning session supported by ERIS’ vision modules – which feature depth sensors alongside 16 high-resolution cameras with auto-focus lenses to prevent errors caused by deviations in shelf distance – the system gathers and analyses relevant stock information in-situ, such as from printed and electronic labels, barcode locations and OSA (on-shelf availability) estimation.

“The robot takes images from all the cameras simultaneously and builds a single large vertical image, almost two metres high, as long as the shelf,” said Mihai Crăciunescu, “Once it has discovered the areas with the price tag, it can identify the barcode and read the price. Once it has all this information, it can query the current product price against the retailer’s updated database.”

ERIS1 in Store. Image: Adapta Robotics

Human operation provides an immediate solution

Using AI algorithms, ERIS uses its images to determine price inconsistencies and estimate forthcoming stock problems. Should issues be found, however, ERIS’ human operator is then able to rectify them in an instant, printing and replacing incorrect labels or restocking the shelves after being issued with a warning.

“With ERIS, we decided from the beginning that it must be operated by a human. Thus, we make the pipeline more efficient, as the operator can solve the problems that arise on the spot,” said Mihai Crăciunescu. “The accuracy of the entire system is over 98%, in some cases even 100% because the entire flow has been optimised to work as well as possible in a real store environment.”