BMW and Tesla are two high-level car manufacturers who have recently revealed plans to position humanoid, AI-powered production robots into their manufacturing processes.

The use of robotics in automotive production is nothing new. First used on assembly lines in the early ‘60s, those early pioneers of automation featured hydraulic or pneumatic arms and were mostly used for heavy lifting. The addition of miniaturised motors, gyros, servos and microprocessors to control it all saw them diversify their skill sets into bolt tightening, before sensors and cameras were added to include quality control.

The majority of production lines, however, still use robotics and automation in a very one-dimensional way – despite sometimes using 3D vision cameras. Unaffected by the boredom of monotony, these machines are pre-programmed to complete one task and one task only, be it to position one component alongside another or to weld the two together. Because of this, multiple machines are required to perform the overall task, making an entire production line’s robotic equipment a costly investment.

Multi-skilled humanoid robots can take the jobs humans don’t want

Within all of this, of course, there’s the looming question of human jobs. Any discussion about automation invariably includes the decreasing number of human employees required. The automotive industry, however, where the rise of simpler-to-build electronic vehicles is already meaning reduced jobs, claims there are millions of jobs it’s finding it hard to fill. Figure, a start-up that is developing humanoid automation robots for commercial use, suggests that there are 10 million unsafe, undesirable and unfilled jobs in the US alone, and that this represents a large gap for capable humanoid robots to fill.

“Single-purpose robotics have saturated the commercial market for decades, but the potential of general-purpose robotics is completely untapped,” says Figure’s founder and CEO, Brett Adcock. “[Humanoid} robots will enable companies to increase productivity, reduce costs and create a safer and more consistent environment.”

Tesla hopes its humanoid robot Optimus will be commercially available in 2026. Image: Tesla

Designing a model employee

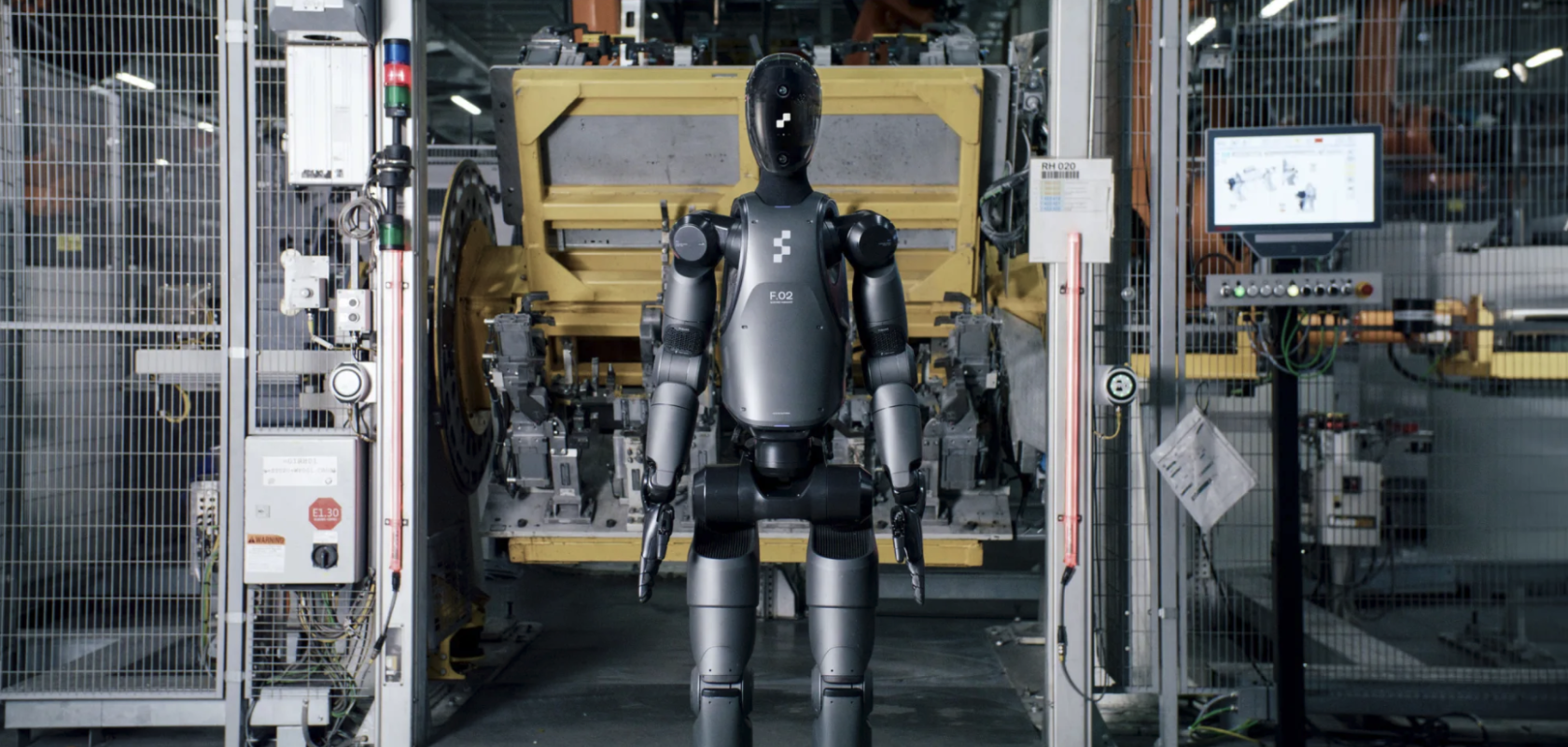

Released in 2023 alongside credentials such as a 2.7 mph top-speed, <20kg weight capacity and operating for up to five hours before needing to recharge may make Figure’s initial 01 model sound like a poor quality co-worker, but the latest Figure 02 version features twice as much energy, six on-board machine vision cameras for improved physical awareness, hands with 16-degrees of freedom capable of a range of human-like tasks, common-sense reasoning using a vision language model, three times the computational power of Figure 01 – helping it to perform real-world AI tasks autonomously – and custom AI models make it capable of speech-to-speech conversations.

The redesign of Figure’s hardware and software offering, as well as a collaboration with OpenAI, has been part of a decisive effort to help the robot communicate and collaborate with humans, alongside enhancing manufacturing productivity and efficiency. Receiving a total of $675m in Series B funding, the developer has also been working with BMW Manufacturing, who has been testing the robot for data collection and application training.

Hyundai has started using Boston Dynamics' Spot robot to perform quality control checks at its manufacturing facility, after the firm's acquisition of the tech company. Image: Hyundai

Other factory-based humanoid robots

Elsewhere, after the car company’s acquisition of Boston Dynamics, Hyundai has been using Spot, Boston Dynamics’ four-legged walking robot, to carry out quality control at its production sites. Other tasks Hyundai has given Spot outside the factory include working in dangerous environments like Covid wards to monitor patients’ vital signs, reducing the risk of contamination.

Tesla’s humanoid robot, Optimus, meanwhile, has been developed to perform any task that’s boring, repetitive or dangerous such as grocery shopping, fixing vehicles or building houses, respectively. Previously suggesting that Optimus could serve as a personal butler, and predicting Tesla’s robotics division to one day eclipse the car business, Elon Musk plans to commercially release the robot in 2026. Before then, however, trials are planned to introduce Optimus into Tesla’s own factories as early as 2025.