Imaging and Machine Vision Europe is thrilled to announce the shortlist of entrants for the esteemed VISION Award 2024. The award, which celebrates excellence and innovation in the imaging and machine vision industry, attracted an impressive 60 entries this year, highlighting the sector’s dynamic growth and potential.

A jury awards the best innovation from the field of machine vision with a prize of €3,000, which is sponsored by Imaging and Machine Vision Europe (IMVE).

The shortlisted companies and individuals represent a diverse range of applications and technologies, showcasing the industry’s ability to address complex challenges and drive progress across various sectors. From groundbreaking research and development to successful commercial deployments, the finalists demonstrate the power of imaging and machine vision to transform industries and improve lives.

In alphabetical order, this year’s shortlisted entrants are:

- AiRob Vision Systems (part of Fideltronik Group)

- AIT

- Murrelektronik

- PxE Holographic Imaging

- Toshiba Teli corporation

When will the VISION Award winner be announced?

The one-hour VISION Award session will take place in Stuttgart on Wednesday, 9 October, 2024, from 11:00-12:00 at

Hall 8, Booth C70. All the shortlisted entrants will have the opportunity to present their innovations. At the end of the session, jury member Chris Yates will crown the winner and the prize will be given.

The session will be moderated by Warren Clark, the chief executive of IMVE owner Europa Science, who said: “Imaging and Machine Vision Europe has been the Vision Award sponsor for more than 20 years and we're very proud to continue that tradition into 2024. With its focus on innovation and driving intelligent vision forward, the Vision Award is aligned with our own values, particularly as we launch our new content stream, Visionaries.

“Visionaries is focused on the integrators helping end users directly – and all integrators need the right technology for their applications. We congratulate all entrants on their commitment to problem-solving through new techniques and we look forward to seeing these new technologies on the front line of machine vision inspection and beyond.”

Previous recipients of the VISION Award, such as Kitov.ai’s Yossi Rubner and Prophesee’s Luca Verre have been featured in the annual Photonics100 list of photonics innovators, published by IMVE’s sister title Electro Optics.

AiRob Vision Systems

Based in Wrocław, Poland, AiRob Vision Systems’ entry is entitled ‘VIS Expert: Integrated Quality Assurance System for Electronic THT Component Assembly’. In the award entry, CEO Dariusz Hebisz states that VIS Expert is an integrated quality assurance system for electronic through-hole technology (THT) component assembly, designed to enhance the quality of printed circuit board assembly (PCBA) production and electronic products while reducing costs.

AiRob believes VIS Expert showcases the potential of AI-enhanced vision systems in industrial applications and that its ability to provide real-time, high-accuracy defect detection makes it invaluable for quality assurance in electronic manufacturing.

“This system leverages cutting-edge vision technology supported by AI within a unified ecosystem, providing real-time defect detection and analysis to improve production efficiency and product reliability,” states Hebisz.

“The system supports continuous process improvement through detailed analytical data and facilitates rapid deployment and scalability, making it a versatile solution for dynamic production environments.”

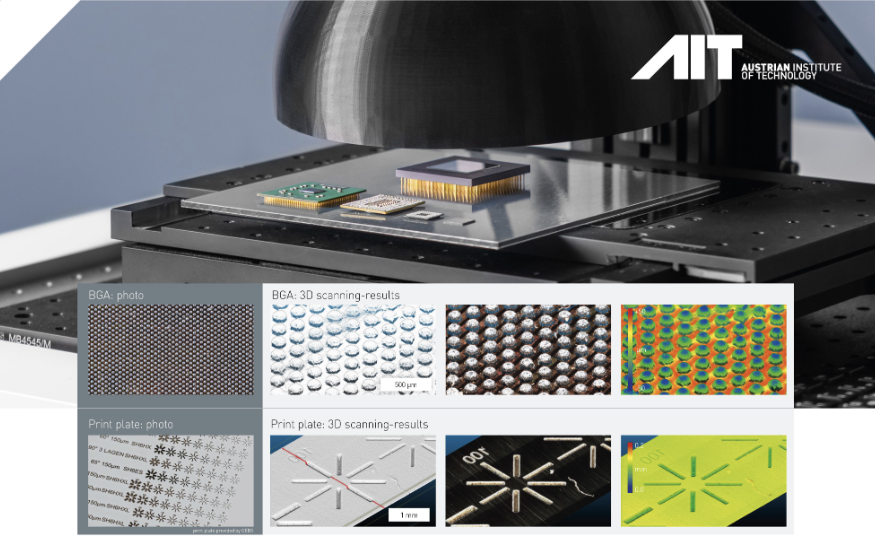

AIT (Austrian Institute of Technology)

AIT’s shortlisted entry, ‘100% Inline Combined 2D/3D Microscopy’ was written by Clabian Markus, Traxler Lukas and Thanner Petra, and presents a technology that they say will enable 100% inline combined 2D and 3D inspection in microscopy for the first time.

Their entry states that the innovation offers sampling rates of up to 700nm and delivers up to 60 million registered 2D image pixels and 3D points per second, making it particularly suitable for high-quality manufacturing industries and industrial processes where continuous movements occur in the process line.

According to AIT, the benefits to the end user include:

- Fast and precise quality control: 2D and 3D inspections are combined in a single camera with standard optics. This allows comprehensive inspection of moving parts in real time.

- High resolution and accuracy: resolutions in the single-digit μm range (x/y/z) enable precise inspections at the microscopic level.

- Efficient use of parallax effects: Instead of avoiding parallax effects, they are utilised to achieve fast and precise 3D depth reconstruction.

- High scanning speeds: up to 12 mm/s with a depth resolution of 2.8μm and a lateral sampling of 700 nm/pixel.

Murrelektronik

Murrelektronik’s entry bids ‘Bye-bye control cabinet’, stating that its Xelity Hybrid Switch simplifies machine vision system connectivity and can cut costs significantly by saving thousands of metres of cable and reducing installation time. Author Simon Knapp describes the innovation as “revolutionising” the connectivity and networking of machine vision systems.

Xelity Hybrid Switch acts as a local hub for the power, data, and trigger signals of a vision system, allowing system designers to avoid complex and costly long-range connections to control cabinets on the factory floor. Cameras and peripherals such as lighting, sensors etc. are all connected to a small, ruggedised switch located at the inspection cell.

The hybrid switch, which is IP67 compliant, uses standard screw-locked M12 connectors and supports Gigabit Ethernet, distributes both power and data to all components of the vision system. It can power and trigger up to four cameras simultaneously or cameras and strobe lights. Murrelektronik says the system is highly scalable thanks to daisy chain connectivity.

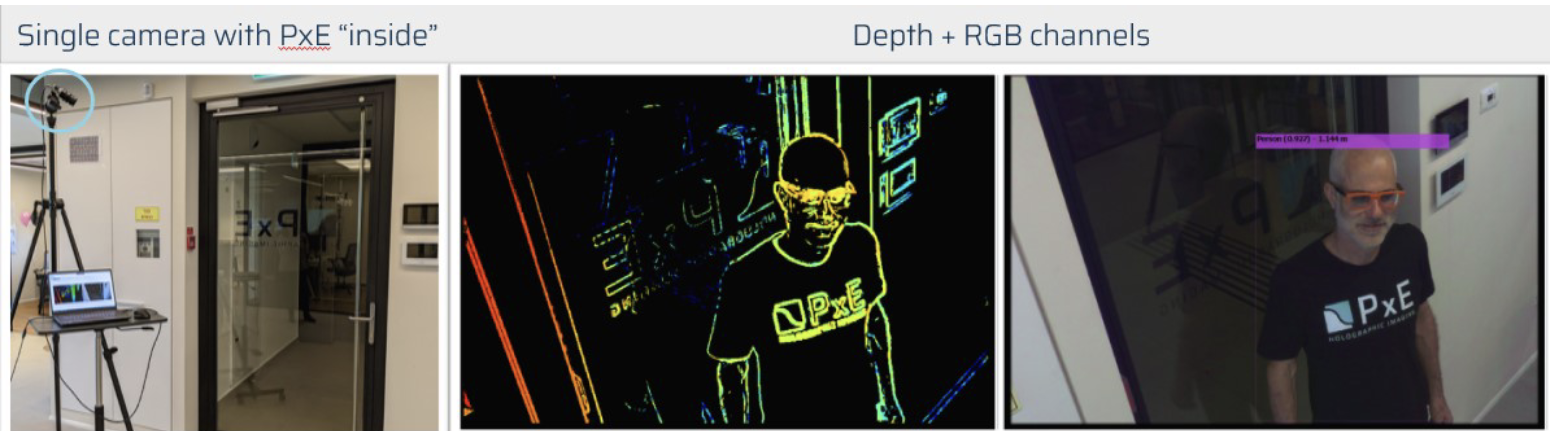

PxE Holographic Imaging

PxE’s entry harnesses the principle of duality (treating light as both a particle and a wave) to deliver a groundbreaking holographic 3D imaging technology.

By replacing the traditional Bayer filter with a holographic optic, PxE’s camera captures colour, infrared, and depth data simultaneously in a single snapshot. It says this overcomes the limitations of light-field imaging, delivering high-resolution images even in low-light conditions. PxE says the technology, which uses a combination of hardware and software, not only improves image quality, but also offers enhanced capabilities such as deblurring, digital aberration correction, and the ability to place cameras in previously difficult locations, such as behind highly curved or raked windshields and display screens.

Using ambient white light rather than lasers with holographic optics also lowers the price, which PxE believes will make the innovation more appealing to industry, by providing a cost-effective, high-performance solution for capturing multiple data points. From autonomous vehicles and robotics to security and industrial inspection, PxE’s technology could offer a significant advantage by combining the cost-efficiency of 2D cameras with the advanced features of 3D imaging.

Toshiba Teli corporation

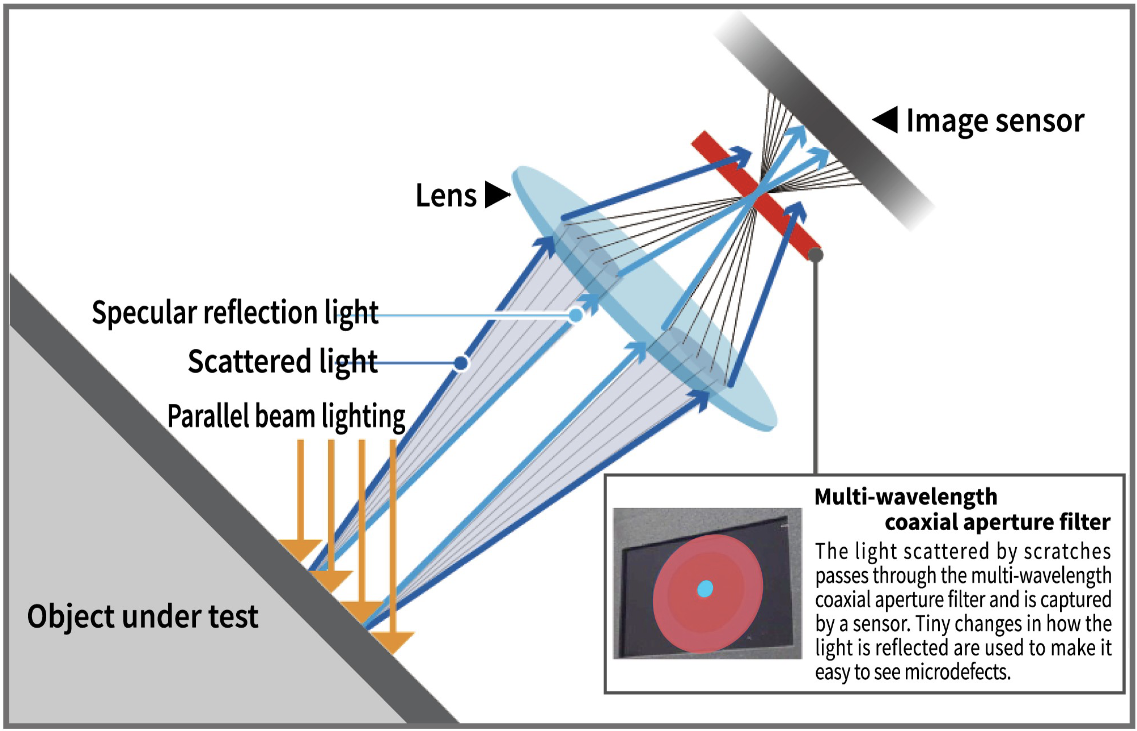

Traditional visual inspection methods have struggled to detect defects on glossy and transparent surfaces. The glare and reflections inherent to these materials often mask imperfections, hindering quality control efforts. Toshiba Teli believes its Surface Flaw Detection Scope, powered by OneShotBRDF technology, overcomes these challenges.

By utilising a special optical filter, this innovative technology separates reflected light from scattered light, caused by defects such as scratches. This differentiation is visually represented as a clear contrast between blue (normal surface) and red (defect), making flaws easily identifiable.

The patented OneShotBRDF technology consists of a special optical filter called a ‘multi-wavelength coaxial aperture’ placed between the lens and the camera, and an illumination device suitable for this technology. Toshiba Teli says this function can be realised solely by the light-receiving equipment, and no special lighting apparatus is necessary.

The Surface Flaw Detection Scope offers significant advantages over traditional inspection methods. It not only detects minute scratches, but also provides a high-speed inspection process and can capture a wide area in a single shot, enhancing efficiency. Beyond defect detection, the scope can also evaluate surface roughness based on colour variations.

This groundbreaking technology has broad applications across industries, including inspection of flat optical filters and hermetic components, such as valves.

What is IMVE Visionaries and how can I get involved?

Visionaries is a ground-breaking initiative from Imaging and Machine Vision Europe designed to celebrate innovators in the field of imaging and machine vision technology.

Throughout 2024, our dedicated content team is embarking on a journey of exploration, conducting exclusive interviews with C-suite executives from leading system integrators, machine builders, and end users who are harnessing the power of vision technology to push the boundaries of what is possible.

You can help us to capture the views of as many of those innovative integrators as possible by filling out this quick questionnaire to tell us about yourself. If you don't think you qualify as a machine vision integrator, but have a contact, a colleague or a client who does, feel free to share this questionnaire with them.