With more than 15 years of experience in nanomaterials and short-wave infrared (SWIR), Finnish firm Emberion sees VISION as the most productive show in its calendar. “The quality of the audience is second to none,” says Jyri Hamalainen, Head of Product Management & Marketing.

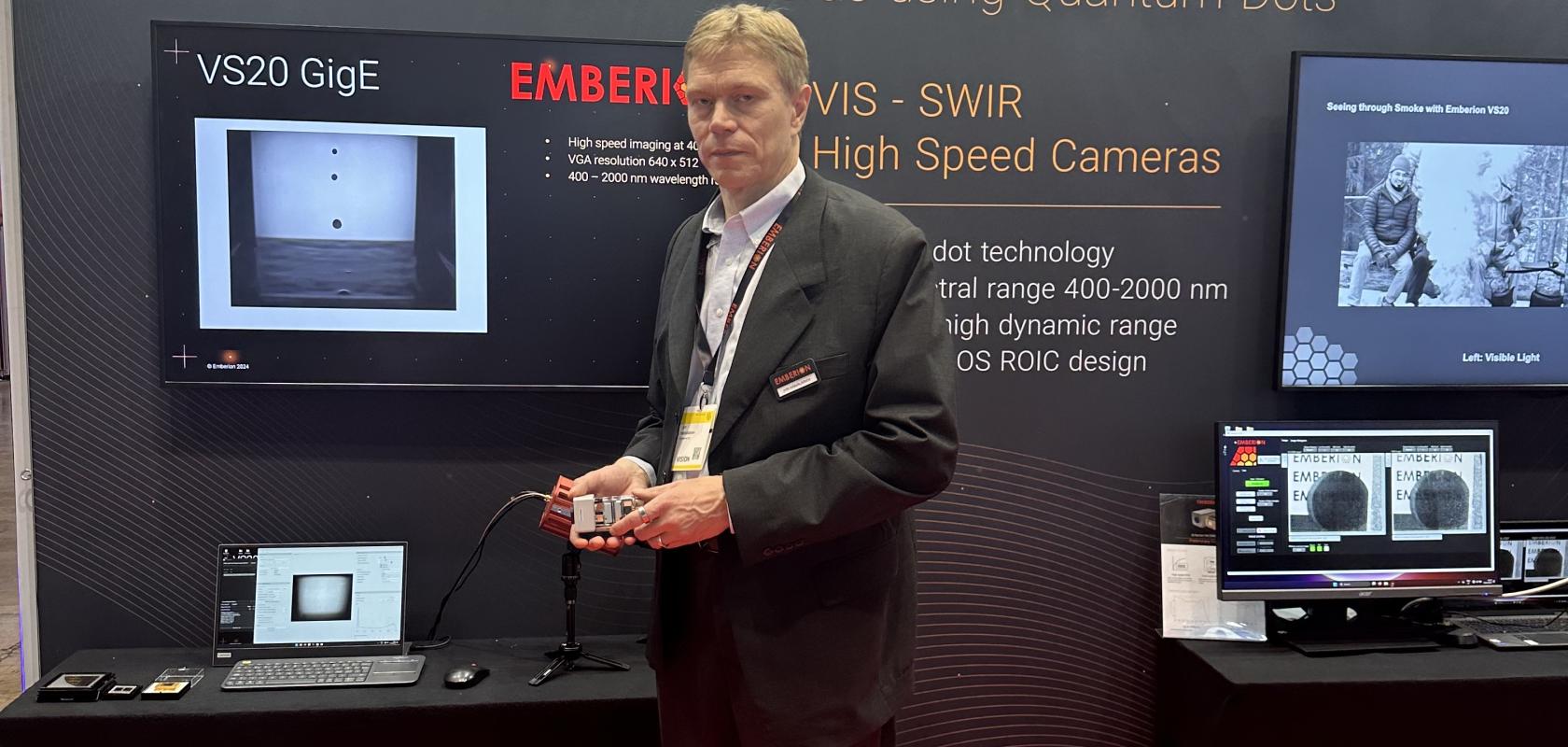

This year’s show is the springboard for three new strands of development set to excite the market in the years ahead. The firm currently has three principal products driving the market: the VS20 GigE; a 400 frames-per-second (fps) high-speed Vis-SWIR camera with GigE Vision Interface; the VS20 Compact, with similar features but in size-, weight- and power-optimised housing; and the VS20 Core, designed for integration into high-volume end applications. All cameras run at 400 fps, and Hamalainen admits that, even last year, there were sceptics who questioned the technology's ability at this scale.”We’re using this show to run a video that slows the 400 fps to 30 fps to showcase this high speed, and we are already shipping this camera,” he says.

“My favourite saying in the company is: I believe when I see it! Now, everyone can see what we are doing today, and this camera has been available since the beginning of the year. Now, we are also flipping the compacts with a smaller housing, and we can see a number of interesting industry applications.”

First on the ‘what next?’ horizon is a powerful new sensor – essentially another version of Emberion’s quantum dot stack. “The key message is that we have now developed a variant , something that works better in certain wavelength areas than our current one, and we have the capability to do so with further variance. Here, we are showcasing one with a spectral peak of 1,620nm. We actually call it the Emberion VS17, going up to 1,700nm plus. There are future capabilities, perhaps even up to 2,500nm. It will depend on customer demand: where I can find the customer case?

“Over 2000 nm is not an easy area to develop but absolutely achievable. It's easier to make a shorter wavelength version. That's a challenge today, or my challenge is to prove R&D to investors. Many customers tell us that 2,000nm is enough.”

“We also have a future product that is designed for pushbroom hyperspectral imaging, a monochromatic sensor for pushbroom, hyperspectral imaging integrators, and I want to demonstrate that we can run fast. At full frame, it will run at 1,000 fps and, with selected spectral lines, it will run 3,000 fps. Now, being able to prove today that our stack can do up to 1,500 fps is a major step. I can comfortably say that it is the fastest quantum dot camera that anyone is doing. I know InGaAs can do faster, but both technologies have their challenges, and I think they also have their limitations.” Emberion brought to the market the fastest quantum dot (QD) based camera running 400 fps full frame last year and has now demonstrated speed of 1500 fps with region-of-interest (ROI) implementations. It sets a new industry benchmark.

“I think 1,500 fps in QVGA is quite remarkable,” says Hamalainen. “When I first saw the team working on this in the lab, it might have been 1,300 at that time, and I thought then that this is impressive”

The final big project is focused on lowering the cost for applications where the volumes are in their thousands or tens of thousands: the ultra low-cost SWIR. The aim is ultimately to produce something at around €50 per-sensor. Emberion has a heritage in Nokia mobile devices, but Hamalainen also senses big opportunities in the automotive, consumer electronics and defence sectors.

“It will possibly have critical use in detecting lasers. If the sensors cost hundreds, you can’t equip every single soldier, and put them in every single helmet you need. Today, this technology might only be built into very heavy equipment. This is more of a product innovation in early development, but we wanted to now start talking to potential customers. The first products with wafer level packaging will be available next year (not yet at €50) but if we can validate it with early adopters, we can bring it to the full-scale commercial stage.”

Like most exhibitors, Emberion admits the year hasn’t been without its challenges. “It has been a little slow,” says Hamalainen, “but it’s picking up again now. We are always in a continuous improvement mode and maturing our technology, and I feel comfortable that now we are again, back on the growth curve.” It’s a positive story for the company, which announced Sami Kyllönen as its new CEO in September. He has previously served as the COO and Director of Production.