Resolve Optics is having a strong year, with a lot of momentum in the space market, but also a strong order book with an established customer base. With a reputation built across more than 20 years of customised lenses and optical designs for a range of small and large clients, Resolve Optics admits some of the biggest successes have to remain under wraps.

“A lot of our customers don't like us talking about what we're doing for them,” says Mark Pontin, the company’s Managing Director. “What isn’t perhaps a secret is the fact that we have been working for the space industry now for the past five to ten years, and that market is growing steadily for us.” At VISION 2024, it was just one of the draws for visitors to the company’s booth.

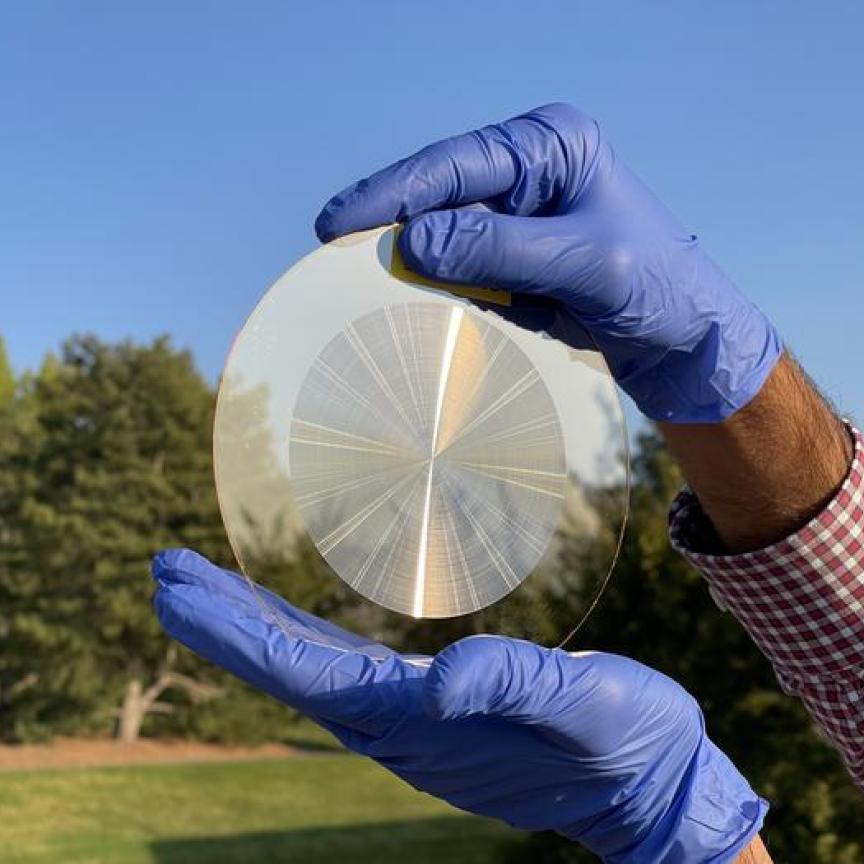

“The optics we’re putting up there in space need to be prepared for a very extreme context, and our expertise in the nuclear industry supports that, especially with our Non-Browning products.” These radiation resistant lenses offer long-term, top performance for an accumulated radiation dose of 100,000,000 rad without significant discolouration or degradation of product.

One of the biggest challenges, of course, for space-destination lenses lies in getting them up into orbit. “We have in-house vibration testing that subjects them to the stress and strains they need to survive during launch to arrive fully intact and ready for operation in space. Generally, space is pretty harmless, apart from the vacuum and the radiation, so the challenge is often simply getting them up there.” Despite the cost of some of the lenses, none will ever make the return journey – it’s simply cost-prohibitive to bring them back down to Earth once their work is completed.

Resolve Optics has always had a strategic focus on the customisation end of the market, and that’s paying dividends in what’s proving to be a buoyant year for the firm. “We will occasionally develop a product where we identify the market wants a particular optical solution, but that's quite rare because, generally, by the time you've developed it, something else has come up,” says Pontin. “We don't aim to compete with the off-the-shelf market and are quite happy to point people to other places if that’s what will ultimately suit them better.”

The company says some space projects take a long time to see the lenses in actual use. “I’m thinking about one satellite customer who we supplied lenses to two years ago, and they still have yet to launch them, but most projects can see their newly developed custom lenses within five to six months,” says Pontin. He reveals most customers know what sensor they want to use, but Resolve Optics usually spends a fair bit of time working with them to work out how to bolt sensors either to the camera or, sometimes, to the lens. “It's surprising how a whole project can evolve from something that seemed quite straightforward at the start,” he says. “We work closely with customers at the design stage of the project to ensure we share a common understanding of the needs of the lens or optical system for their target application. Some know exactly what they want, but nine times out of 10, lens design is more of a process.” That said, Resolve Optics' aim for new approaches is to provide a preliminary optical design, approximate cost and some basic production scoping within a week.

Resolve Optics is rightly perceived as being a bit of a specialist in the radiation-resistant optics field. “Today, we are the leading supplier of Non-Browning lenses to the nuclear, space and medical sectors,” he says. This opportunity came along when Japanese company Fujinon pulled out of the market 20 years ago.

One more specific thing that sets Resolve Optics apart from, say, off-the-shelf suppliers – where lenses can often be discontinued after a time if overall demand falls – is a commitment that, once a custom lens is developed by the company, it will remain available for as long as it is needed. For these custom lenses, there’s also an exclusivity pledge that gives customers confidence about the security of their supply partnership. In addition to Non-Browning, the company also specialises in application-optimised UV, IR and SWIR lenses, as well as zoom lens designs that can be all-function motorised or manual.

Pontin confirms that, aided by its strong sales, the company will continue to invest in new facilities, equipment and people to enhance the firm’s focus on customer service and support. “I would say top performance, and reliable lenses backed by strong customer support, means we're rather good at retaining customers – however this is something we never take for granted” he told Imaging & Machine Vision Europe on the final day at VISION 2024.