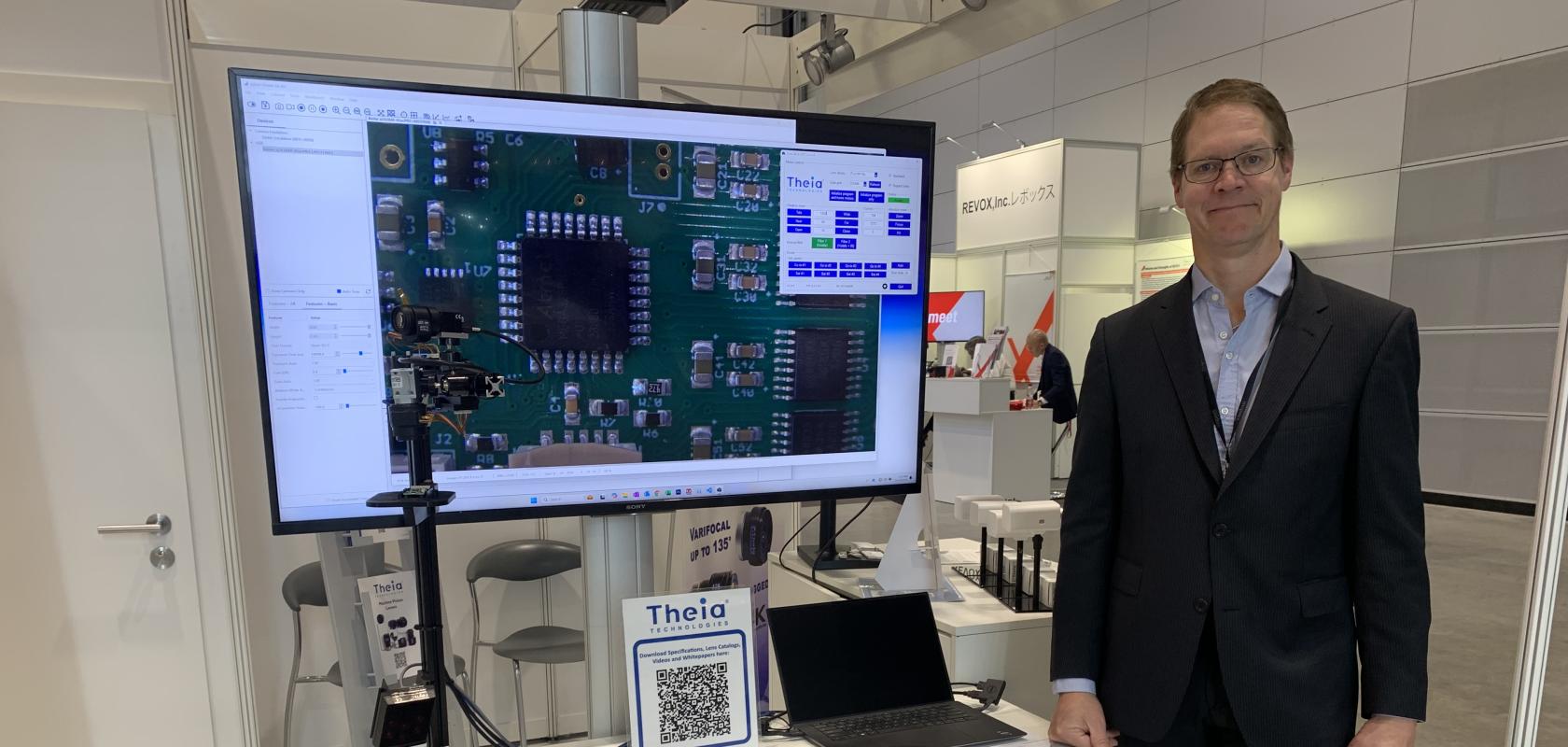

At VISION 2024, Theia Technologies highlighted its range of motorised lenses, which come with supporting software and a user-friendly interface to make it easier to integrate into wider automation systems.

On display were both the 12-50mm lens and the 4-10mm lens, both of which are suitable for very small pixels (down to 1.55um), providing very high resolution (around 300 lines per mm). Both lenses are IR corrected, so are able to focus visible and near IR light in the same plane.

The specially-developed IQ Lens system means each lens is tested at 4 different object distances and 13 different focal lengths.

Andrea van Landingham, partner and Vice President of Business Development at Theia Technologies, says, "We measure and calculate what the best focus position for those settings are and incorporate that into a file. This file is then available to be pulled into the image processing system, enabling the user to quickly find the focus after they change the zoom position.

"The lenses also have an integrated filter that allows users to cut out IR light or to transmit either 850nm or 940nm light (depending on the lens model), enabling use in multispectral applications.

"The 12-50mm lens is particularly suited to intelligent traffic systems (ITS), where it is used for automated number plate recognition (ANPR) at a range of up to 140m or more, depending on the camera resolution and the AI engine used."

The 4-10mm lens is ideal for autonomous motorised robots (AMR), where it can be used to read barcodes on shelves to check for product outages or pricing accuracy. The high resolution performance allows it to read the fine detail. It has also recently been adopted in an automated laboratory testing system for monitoring petri dishes over time.

There are several aspects to these lenses that make them different from other products on the market, according to van Landingham: "The supporting intelligence and software allows users to find the focus quickly, as well as enabling them to translate other engineering settings, such as field of view in degrees or object distance in metres, into a motor step. The motor control board software then converts this motor step into lens commands to move the lens to the desired position.

"Another differentiator is that our motor control board has multiple communication protocols. As well as USB, we have UART and I2C protocols, making it more versatile and easy to integrate.

"Further flexibility is achieved by the ability to interchange filters at the push of a button, which is useful if the user wants to view objects at a particular wavelength.

"Our lenses offer much higher resolution than most traditional machine vision lenses, which otherwise tend to go to around the 3um pixel. By going down to 1.55um, we’re able to provide great image resolution in both visible and near IR. Whereas many lens set-ups might require a separate lens to achieve this performance, we can offer multiple focal lengths and wavelength capabilities in a single lens, making it a very robust and versatile choice.

"Finally, the entire system is modular. The board and the lens are separate. This compact and flexible design opens up a whole host of different applications in lots of different settings."

As well as the motorised lenses, Theia Technologies also highlighted a new ultra wide lens, which uses a patented technology that removes barrel distortion in the optics without software correction. The newest model to employ this technology platform has a unique combination M12 with C-mount and ruggedised design, which has allowed its use in automotive interior crash testing.

"Software correction requires some processing time," adds van Landingham, "so that creates latency. With ours you get the straightened image immediately out of the lens, so there’s no delay in processing.

"The other thing that’s unique about the product from a wide angle lens standpoint is that most fisheye lenses will have compression all the way around the edge of the image; that compression means you’re losing resolution at the edge.

"We actually have more pixels as you go out to the edges, meaning you will definitely have higher resolution compared to a fisheye lens, as well as a better chance of identification out at those edges compared to other wide angle lenses.

"From a use case perspective, this makes it suited to a close focus environment, where you want to be able to inspect everything across the entire field of the lens, including defects right at the edges."