As a complete machine vision solution provider in manufacturing, automotive and logistics automation, Co-Founder and Manager of Swedvision, Tommy Svedlund, talks to Imaging & Machine Vision Europe about the Swedish firm’s visionary work in the sector.

Name: Tommy Svedlund

Company: Swedvision

Role: Co-founder & Manager

Location: Stenkullen, Sweden

Founded in 1989, Swedvision Automation’s initial focus was on the inspection of refined wood products for flooring and other applications. But over the past 35 years, they’ve grown into a supplier of complete machine vision solutions, branching out into a wide range of sectors and markets such as interior, food and automotive products.

Image: Swedvision

Owned and operated by Tommy Svedlund, alongside Andreas Frostenäs and Dan Parsmo, the firm builds “complete vision solutions for our clients, including MTRL (multi-task reinforcement learning) feeding and sorting,” said Svedlund, when speaking to Imaging & Machine Vision Europe about his and Swedvision’s inclusion in Visionaries 2024. “From initial consultation through to the final installation and ongoing support, we provide the whole project chain, offering pre-investigation, system suggestion and implementation.”

Experience is strength, whatever the market

And it’s this circuitous journey through the ever-changing machine vision sector over the past three decades that, Swedvision believes, gives them their strength in the market. “Our experience of applied automation in various branches of industries and environments is our strength,” says the company, which includes international high-quality flooring manufacturers such as Tarkett and Kährs alongside Volvo Trucks and automotive interiors manufacturer IAC amongst its clients. “We are proud that we have been able to help our customers provide a higher quality and level of automation.”

A visionary integrator: Swedvision project examples

“We work a lot with quality sorting and measuring applications,” said Svedlund, when asked to describe some of the work that qualifies him and Swedvision as ‘Visionaries’. In one of the firm’s oldest sectors, for example, automation allows Swedvision to assist in the sorting and screening of thin wood veneers, using a smart camera for inspection and guidance, before a robot picks and sorts for further processing.

Image: Swedvision

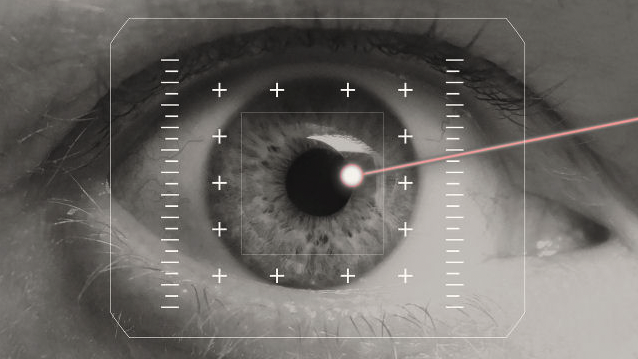

Highlighting the company’s move into other sectors and other materials meanwhile, past work also includes using smart cameras to watch the watchers, ensuring the right amount of glue is applied to the right place in the assembly of in-vehicle camera systems. But the market moves quickly when it comes to camera technology, so when a client’s existing camera technology found itself out of date, Swedvision supplied software that adapted the system to a new camera, future-proofing the verification of steel beams.

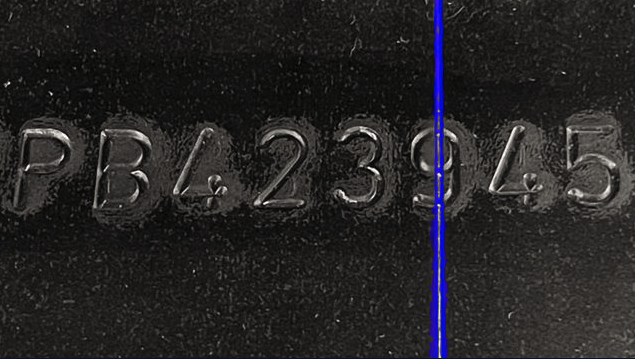

Assisting clients to keep up-to-date with modern technology and contemporary systems is a common theme in Swedvision’s work, having helped an aluminium producer in Norway to expand its operation from one based on 2D analysis to one based on 3D measurements instead, meeting new production demands, and delivering software for the precision guidance of laser marking equipment to facilities in India and Japan.

Image: Swedvision

While opening themselves up to work in new sectors, with new technologies and new materials, there’s still a time and a place to remind oneself of how it all started. Working with a manufacturer of turned wooden bottletops, Swedvision used modern area cameras and 3D scanning to improve the traditional process. Also, robot guidance worked alongside both 2D and 3D inspection systems to upgrade a precision turning manufacturer’s vision systems, helping them to introduce a fully automatic inspection machine to sort through defective products.

Dealing with customer expectations and other major challenges

Dealing with exaggerated customer expectations can be one of the hardest parts of life as an integrator. “We try to work with a reference collection and make a deep investigation before we design a solution,” said Svedlund, when asked how Swedvision deals with the issue of expectation management. “The most common situation after an installation [has been completed] is that the system is too sensitive. But in all cases, it is possible to decrease or adjust the function level.”

So does meeting or managing high customer expectations represent one of the main challenges of machine vision across the board? Svedlund thinks not. “The most important thing is to investigate the need before we design the system. There are strengths and weaknesses in any solution. Also, we need to look at the normal flow of the parts and any variations. In wood-sorting applications, for example, all parts are different so it is a challenge to formulate these sorting rules. Some systems require distinct approaches, while some are more statistical.”

“One of the biggest challenges we face, however,” continues Svedlund, “is in finding competent personnel, and this makes it hard to branch further out into bigger markets.”

Tommy Svedlund has been named as one of Imaging & Machine Vision Europe’s ‘Visionaries’ for 2024. Find out how to apply and nominate others to be recognised as a Visionary for groundbreaking work in the vision sector here.