A high speed camera recently developed by Nasa has successfully recorded a video of the jet propulsion during a test of Nasa’s Space Launch System (SLS) rocket booster. The booster will be part of the most powerful rocket in the world when it's assembled.

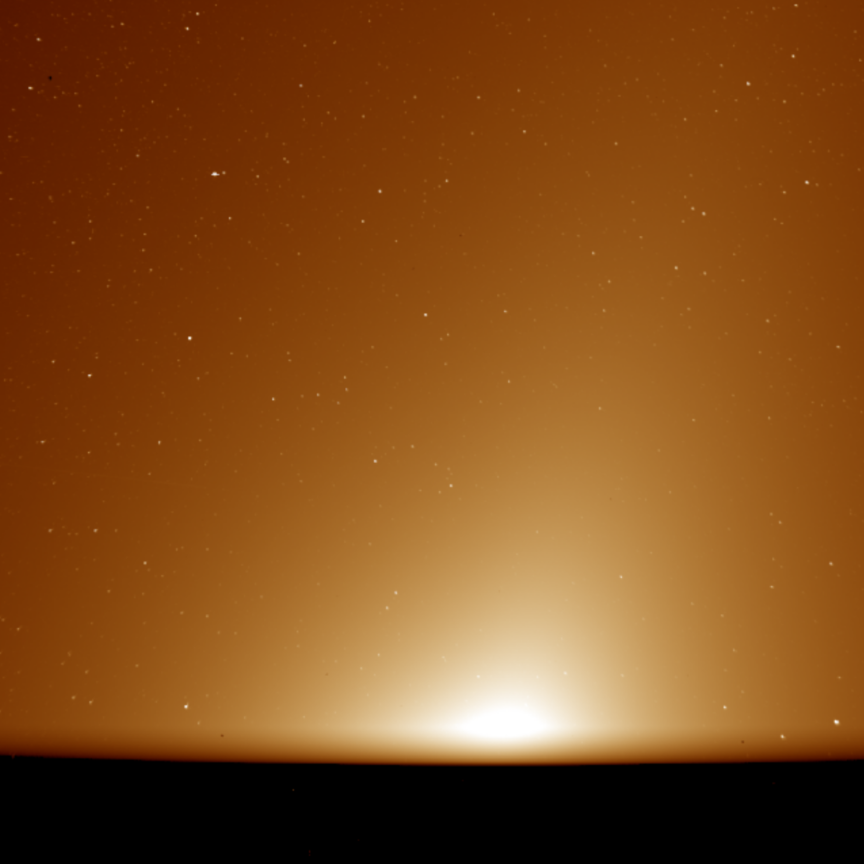

The camera is the result of Nasa’s High Dynamic Range Stereo X (HiDyRS-X) project, which aimed to overcome the problem of filming extremely bright rocket motor plumes without having to reduce the exposure settings. In order to do this, HiDyRS-X records multiple, slow motion video exposures at once and combines them into a high dynamic range video.

The HiDyRS-X project began as part of Nasa Space Technology Mission Directorate’s Early Career Initiative (ECI), designed to give young engineers the opportunity to lead projects and develop hardware alongside leading innovators in industry. Howard Conyers, a structural dynamist at Nasa’s Stennis Space Center, was awarded as an ECI grant in 2015. After initial proof of concept and a preliminary design review, the HiDyRS-X project was placed within Nasa’s Game Changing Development programme to complete its first prototype. Created in partnership with Innovative Imaging and Research Corporation, the project was tested on small rocket nozzle plumes at Stennis.

The recent massive booster test served as a rare opportunity to test the HiDyRS-X hardware in a full-scale environment. The Qualification Motor 2, or QM-2, test was held at Orbital ATK’s test facility in Promontory, Utah, and was the second and final booster test before SLS’s first test flight in late 2018. SLS will be the most powerful rocket in the world.

In moving from the smaller-scale tests to QM-2, Conyers said the most difficult challenges were seen in compensating for brightness of the booster plume, which is several orders of magnitude brighter than what they had tested before. Unlike the smaller scale rocket engine tests at Stennis, boosters are extremely powerful and, once ignited, cannot be turned off or restarted. The HiDyRS-X team had one shot at getting good footage.

Not all went to plan during the recording, but the camera captured several seconds of the two-minute test. ‘I was amazed to see the ground support mirror bracket tumbling and the vortices shedding in the plume,’ Conyers said. The team was able to gather interesting data from the slow motion footage, and Conyers also discovered something else by speeding up the playback. ‘I was able to clearly see the exhaust plume, nozzle and the nozzle fabric go through its gimballing patterns, which is an expected condition, but usually unobservable in slow motion or normal playback rates,’ he said.

HiDyRS-X will continue testing at Stennis, while a second prototype of the camera is built with more advanced high dynamic range capabilities, using data gathered from the past few years of experimentation. The second HiDyRS-X prototype will be made with an improved manufacturing process to enhance the alignment capabilities of multiple exposure settings, a challenge overcome in the first prototype.

Further information: