The new cx4090HS 3D sensor module, which AT – Automation Technology recently launched as the first product of its new C6 series to complement its modular 3D sensor concept, offers customers added value in many ways. Most importantly, it attracts a lot of attention with its unique new features. The implementation of GenICam 3D is an absolute novelty and opens up completely new horizons in the 3D industry. After AT was the first supplier of 3D cameras to pioneer the connection of hardware and applications with the GenICam standard back in the late 2000s, the northern German company is now once again one of the first global technology companies to enable an uncomplicated connection between software and 3D camera via Plug&Play with GenICam 3D for communication with 3D cameras. With GenIcam 3D, specific features are no longer required for communication between the application and the hardware.

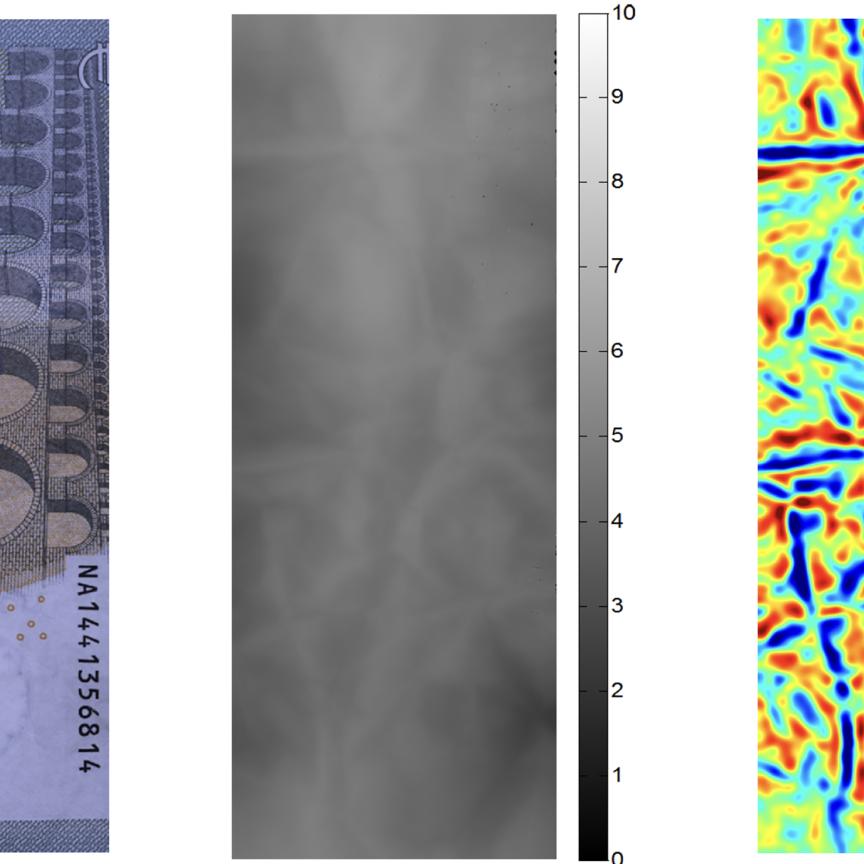

Two further decisive advantages of the new standard interface are the two features MultiPart and MultiPeak. Thanks to MultiPart, it is now possible to output significantly more features, regardless of the pixel format and algorithm. In addition to the height values, the user also receives intensity data, for example. These provide information about the so-called reflectance, which evaluates the contrast display, as well as the scatter value, which analyzes the surface texture. Finally, MultiPeak allows the user to define an exact peak, which means that incorrect measurements due to reflections, for example, can now be ruled out. Thus, both MultiPart and MultiPeak enable the recorded 3D data to be evaluated in even greater detail and the customer benefits from a significantly more comprehensive and stable analysis capability of the 3D sensor.