Keely Portway finds out how combining AI with visual inspection in manufacturing can help to reduce errors and increase efficiency

Artificial intelligence (AI) is increasingly being used in manufacturing and production as a way to help automate a number of processes, ensuring maximum efficiency, minimum errors and a reduction of costs.

One application is in quality control, particularly in industries where the consequences of errors could be particularly high – examples include defence, aero, food production, medicine and automotive.

A recent example of such an investment came in the form of a new Nissan production line at its Tochigi Plant in Japan, which features what the company calls the ‘Nissan Intelligent Factory initiative’. Visual inspection is one of the many processes that will be automated, with 11 robots inspecting the body and bumper in order to achieve 100 per cent detection of dust and debris on the paint work. Another six robots conduct inspections of specifications to identify flaws. Results are stored on a centralised management system for maximum traceability.

Working together

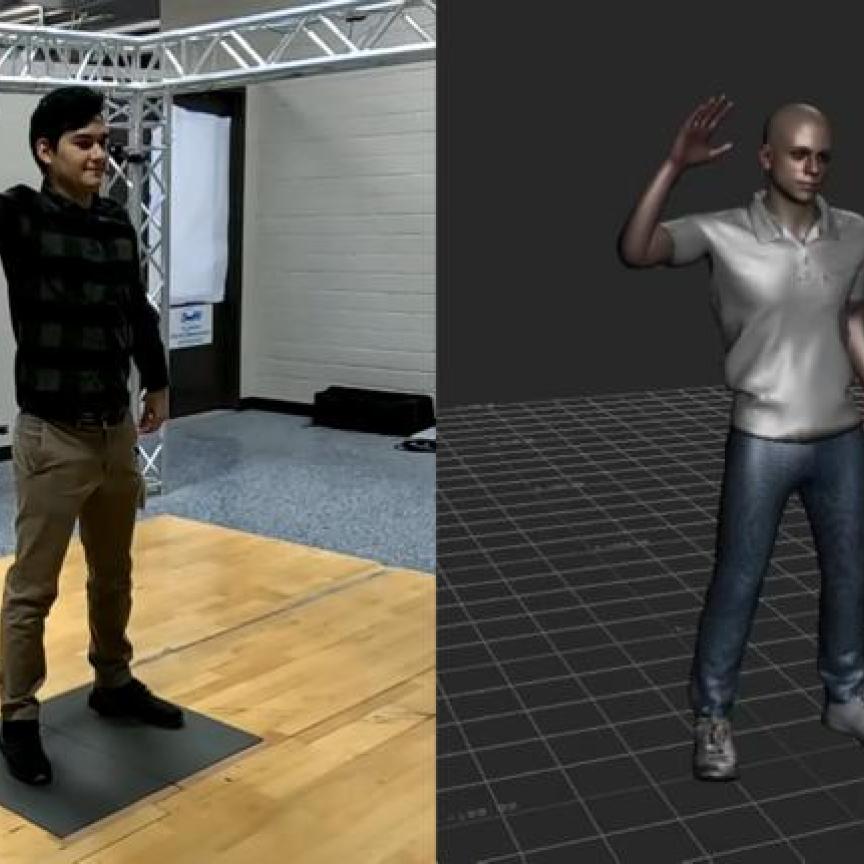

Of course, every inspection process differs depending on company size and product type, among many other factors. Additionally, though challenges to AI adoption have historically centred on the perception that it will replace human workers, it is accurate to say that in many quality control scenarios, visual inspection by human workers combined with AI technologies actually produces the best results.

This is the view held by Ed Goffin, marketing manager at Pleora Technologies, a company that provides AI for manual and automated inspection across a wide range of industries. He said: ‘We have good relationships with a number of customers in different types of markets – we ask them about their manufacturing processes and where they see areas in which they could use technology to help. One thing that consistently comes back to us is that there’s still a heavy reliance on visual inspection in a lot of different areas of manufacturing. No matter how much manufacturers incorporate automation and machine vision, there’s clearly still a pretty big role for humans in the inspection process.’

This is because humans have many skills that lend themselves perfectly to performing visual inspection. Humans can also use their senses to aid visual inspection- in food and beverage manufacture, for example – and we have the ability to learn what sorts of things to look out for from other humans and make subjective decisions. Continued Goffin: ‘Many of the advances in machine vision and now AI aim to replicate what we as humans do really well. But at the same time, we can get tired or distracted, particularly after an eight- or twelve-hour shift. Attention to detail can start to slip.’

In Goffin’s experience, one of the greatest advantages of using AI is to add decision support to visual inspection. ‘It’s not looking to replace humans because we bring a lot of value in those types of manufacturing processes, particularly for lower volume but higher value products,’ he said. ‘The intent is to provide an inspector or operator with the decision support tools that highlight product differences or deviations, or guide them through the manufacturing process to ensure they’re using the right components at the right time.’

This is particularly the case when it comes to visual inspection tasks for consumer goods, food and beverage, print and packaging and manufactured parts (for example, for automotive assemblies). Electronics assembly lines present a particularly big opportunity for AI assistance. ‘One of the areas where AI visual inspection is used the most is for incoming, in-process and final inspection for electronics manufacturing,’ revealed Goffin. ‘In particular, the system is used for higher value, lower volume products not well-suited to full automation, or to help catch errors commonly missed by automated optical inspection.’

Efficient integration

The latest advances in no-code algorithm development and edge processing platforms have made it more feasible for manufacturers of products like those detailed above to incorporate AI decision-support. ‘Pre-packaged and easily trained plug-in applications around common use cases mean manufacturers can get up and running quickly,’ said Goffin.

The added advantage is that it helps to overcome some of the other perceived challenges of incorporating AI into manufacturing processes, in terms of time and expense. Goffin continued: ‘Typically when manufacturers think about AI, there’s a perception that it takes a lot of images and training time, or external expertise is required. There’s also terminology that comes with the technology which can be confusing. So it could be a little bit daunting – especially for a smaller manufacturer who is reading about the advantages of AI, but then trying to understand how to deploy it. Some companies see the advantages of AI, but they also have proven processes that they don’t want to risk. However, today’s systems are designed to be user friendly. So even with just one good image, a manufacturer can start incorporating AI into its existing processes.’

One company that has taken advantage of the benefits of such a system is electronic component manufacturer DICA, which manufactures high-quality electronic assembly services for a small-to-medium volume market. Not all of the company’s products are suited to automation; human inspection is still very important, ensuring that the right components are being used in the right places and that nothing has changed or become defective since the previous step.

Electronic component manufacturer, DICA has incorporated the image compare plug-in from Pleora to incorporate AI into its visual inspection process

DICA has adopted the image compare plug-in from Pleora Technologies to incorporate AI into its visual inspection process. The tool is a visual application that is ‘trained’ to make errors obvious to a human inspector. All that is needed is a single image of a known good product to which all future products can be compared.

The plug-in’s AI capabilities are used to match the approved layout and final production – it compares the placement of components on the circuit board, highlighting any differences for the human inspection before moving on to the next step in the manufacturing process or to final packaging. The plug-in also learns and is continuously trained as the operator accepts or rejects possible detected errors, allowing the system to make more accurate suggestions.

The plug-in is also used for quality checks on incoming components from suppliers and for batch tracking. With an image save application, the operator captures an image of the final board, the barcode and can add any notes on the product. ‘Visual inspection is often a “data black hole” in manufacturing processes,’ said Goffin. ‘This application lets them know a product has left the manufacturing sites in good working order and can speed up the resolution process if there’s an issue in the field.’

Find out how AI can provide decision-support for visual and manual tasks throughout incoming, in-process, and outgoing (final) inspection steps of manufacturing by downloading the latest white paper.